The PCO-7125 is a compact and economical OEM pulsed-current laser diode driver module. It is designed to provide extremely fast high-current pulses for driving laser diodes in range finder, LIDAR, atmospheric communications and other applications requiring high-current nanosecond pulses. This module offers variable output current from 500 mA to 5000 mA with pulse widths from 34 ns to 1 μs at frequencies up to 865 kHz.

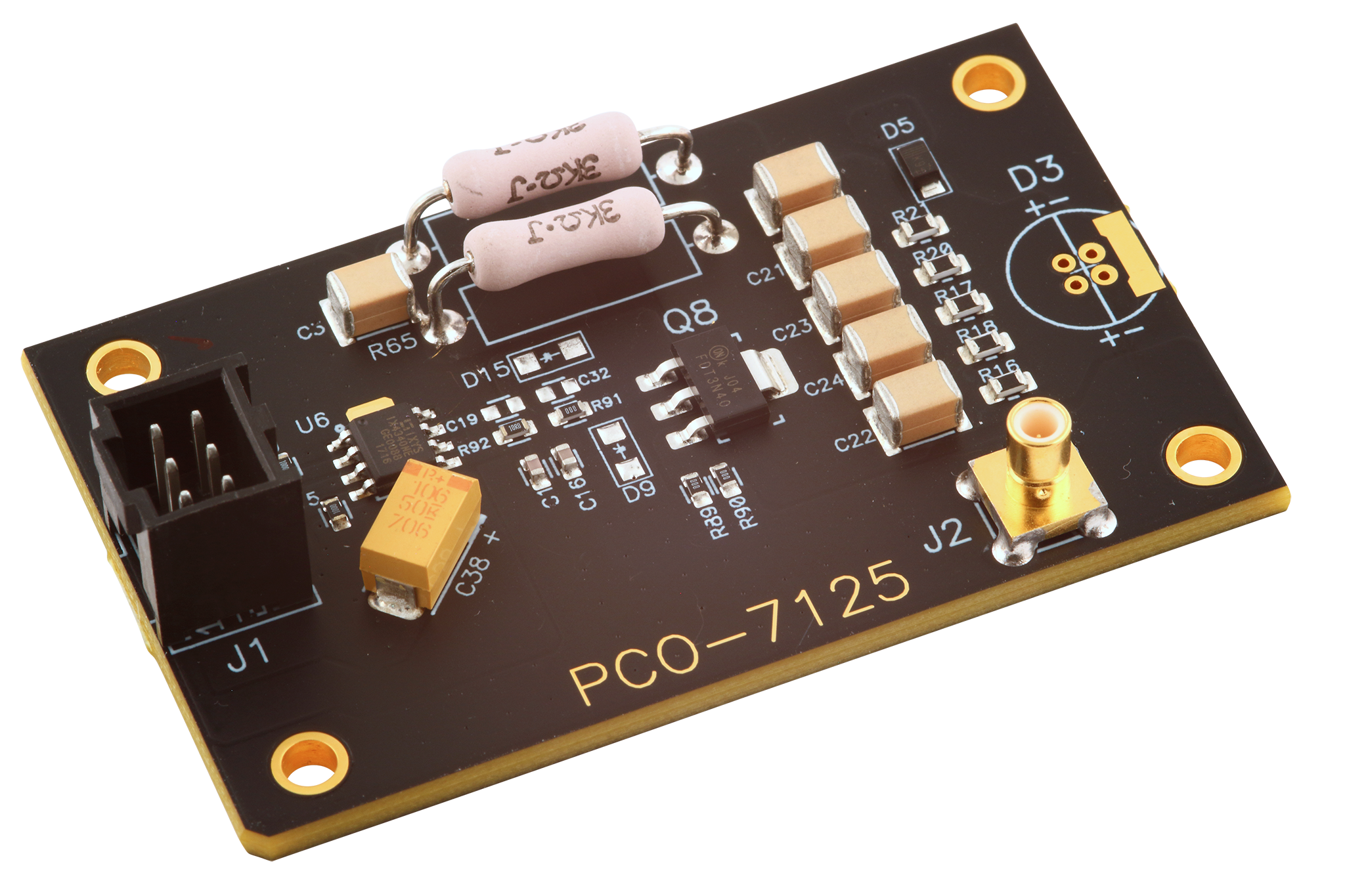

Mounting pads are provided to mount the laser diode directly to the driver. The four-hole mounting pattern accepts TO-18, TO-5, TO-52, 5.6 mm, and 9 mm packages.

The DC high voltage and +12 VDC power supplies are connected via J1, a six-pin male header connector, using the supplied control cable. Pulse current depends on HV supply voltage over the range of 0 V to +200 V (maximum). Externally-generated pulses are fed to the gate input via J1. The width and repetition rate of the gate pulses directly set the timing of the output pulses.

A current monitor output is provided to observe the diode current in real time with an oscilloscope.

Four mounting holes are provided.

Features

- Continuously Adjustable Pulse Width from 34 ns to 1 µs

- 500 mA To 5 A Output

- Pulse Repetition Frequency To 865 kHz

- Pulsed Current Monitor Output

- 34 nS Minimum Pulse Width

Applications

The PCO-7125 is designed to provide extremely fast high-current pulses for driving laser diodes in:

- Range finders

- LIDAR (Light Detection And Ranging)

- ADAS (Advanced driver-assistance systems)

- Other applications requiring high-current nanosecond pulses